You require a Cookeville builder who knows local zoning overlays, stormwater requirements, and Tennessee Energy Code amendments—and also coordinates utilities, inspections, and submittals without delays. Expect kiln‑dried, grade‑stamped structure, ICC/ASTM‑listed envelope components, and third‑party verified tests (air pressure, duct tightness, IR) connected to inspection milestones. Receive a baseline schedule with critical path, documented RFIs/change orders, and closeout packages set for CO. We also model energy targets (≤3 ACH50), spec heat pumps, and pre‑wire EV/solar so your project performs—and what follows explains how.

Essential Highlights

- Comprehensive Cookeville expertise: permitting, zoning overlays, stormwater, Tennessee Energy Code, and utility coordination for accelerated approvals and fewer setbacks.

- Verified materials and workmanship: verified products complying with ASTM/ICC/ANSI, audited submittals, and envelope components selected for Cookeville's humidity and temperature swings.

- Comprehensive inspections and testing: organized checkpoints, independent audits, duct and pressure testing, thermal imaging scans, and documented adjustments for code-compliant performance.

- Open project controls: detailed estimates, cost codes, milestone-tied payments, critical-path scheduling, tracked RFIs/change orders, and stamped plans on site.

- Energy-optimized, move-in ready builds: ≤3 ACH50 air-sealing performance, heat pumps, balanced ventilation, EV and solar-ready, regulatory safety compliance, warranty documents, and Certificate of Occupancy support.

Why Opting for Local Builders Makes a Difference in Cookeville

Close proximity improves outcomes in Cookeville's residential construction. When you partner with local builders, you access Local expertise on city permitting, zoning overlays, stormwater standards, and Tennessee Energy Code amendments. They map site constraints accurately-soil class, frost depth, wind exposure, and floodplain data-so plans meet code on the first submittal. You sidestep delays, change orders, and scope creep.

Regional teams collaborate swiftly with utility providers, inspectors, and suppliers, compressing lead times and reducing weather and logistics risks. They select materials proven for Cookeville's humidity and temperature changes, minimizing callbacks and warranty claims. Community reputation maintains their accountability; they cannot disappear after punch-out. You get clear scheduling, documented inspections, and compliant closeout packages. Choose local, and you manage risk, budget, and schedule with data, not guesswork.

Craftsmanship and Quality Standards You Can Trust

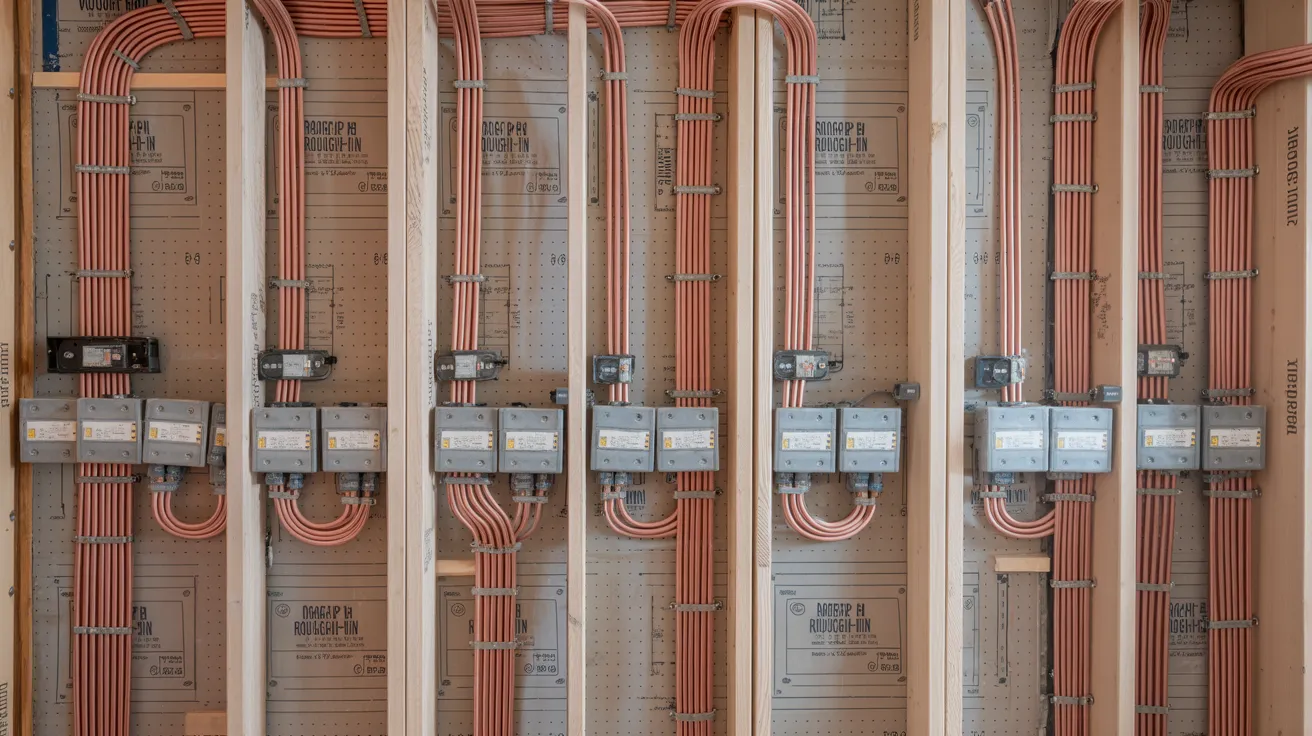

You require craftsmanship that starts with premium materials identified for structural integrity, moisture resistance, and code compliance. We designate certified products, verify batch data, and document chain-of-custody to lower failure risk. You also get rigorous build inspections at each milestone-foundation, framing, MEP rough-in, and final-using checklists adherent to IRC/IBC and manufacturer installation standards.

Quality Materials Selection

Identify materials that satisfy or surpass relevant ASTM, ANSI, and ICC standards, then check traceable certifications ahead of procurement. This minimizes lifecycle risk by choosing products with third-party labels (UL, NSF, GREENGUARD) and documented performance, origin, and batch data. Prioritize Class A fire ratings where required, low-VOC finishes, and corrosion-resistant fasteners per exposure category.

When specifying structural elements, require kiln-dried, grade-stamped lumber; engineered wood featuring APA stamps; and concrete mixes with submittals confirming f'c, slump, and air content. For finishes, specify Exotic hardwoods with FSC or SFI chain-of-custody and Janka hardness appropriate for traffic. Choose Luxury fixtures with ASME A112 compliance, WaterSense certification, and solid-brass or 316 stainless assemblies. For envelopes, require ASTM E2178/E2357 air barriers, ICC-ES listed flashings, and manufacturer-compatible sealants.

Rigorous Construction Inspections

With materials validated against ASTM, ANSI, and ICC requirements, the essential safeguard is a structured inspection protocol that ensures installation meets blueprint, code, and manufacturer specifications. You'll see disciplined checkpoints at layout, foundation, framing, MEP rough-in, envelope, and finishing phases. We document tolerance levels, fastening schedules, vapor control layers, firestopping, and egress parameters. Inspectors validate load paths, nailing patterns, and penetrations against approved drawings.

We utilize systematic snagging to catch defects early, eliminating rework and latent risk. Moisture detection, torque checks, and IR thermography validate performance. Electrical systems and plumbing are subject to pressure, continuity, and GFCI/AFCI tests. Ventilation and insulation are tested to RESNET and IECC targets. Independent third party audits verify conformance and provide corrective actions. You receive comprehensive reports, photo evidence, and closeout verification.

Clear Budgets, Timelines, and Interaction

Often overlooked, open financial planning, feasible deadlines, and transparent dialogue are non-negotiable controls for a standards-compliant, low-exposure build. You should receive precise quotations aligned with scope, technical requirements, and allowances, with itemized costs and contingencies specified. Insist on detailed cost breakdowns that align with schedule activities, so cash flow matches progress. Tie payment milestones to inspection stages and code compliance points, not vague completion claims.

Set a baseline schedule with critical path tasks, long-lead items, and weather buffers documented. Demand regular updates that show percent complete, variance, and recovery actions. Require RFIs, change orders, and submittals tracked in writing with timestamps, responsible parties, and approval deadlines. Employ a single communication channel, meeting cadence, and decision log to prevent scope creep, delay claims, and budget erosion.

Customized Design: From Idea to Move-In Ready

Sound controls only work when the design supports them. You begin with needs analysis, codes, and constraints, then iterate Layout options that fulfill egress, span limits, and plumbing stacks. You validate structural loads, fire separation, and acoustic assemblies early to prevent rework. During Site planning, you reconcile setbacks, drainage, driveway slope, and utility taps, documenting constraints in the survey and civil plan. You coordinate MEP rough-ins with wall types to preserve STC ratings and service access. Finish selections adhere to performance: slip resistance, VOC limits, warranties, and cleanability, all cross-checked with manufacturer specs. You schedule inspections by phase, verify tolerances, and issue punchlists. Finally, you plan Move logistics—protective floor paths, door clearances, appliance routing—so you occupy on time without damaging completed work.

Energy-Saving and Smart Home Building Solutions

Usually, you initiate by configuring the envelope and systems to hit code-mandated performance benchmarks (IECC/ASHRAE 90.1 or local stretch codes) and then specify components that accommodate those loads with buffer. You'll designate R-values, window U-factors/SHGC, and airtightness targets (≤3 ACH50) to dimension heat pumps and ERVs precisely. Focus on continuous exterior insulation, advanced air sealing, and balanced ventilation with MERV-13 filtration.

Choose variable-speed heat pumps, heat pump water heaters, and induction cooking to reduce onsite combustion dangers. Pre-wire circuits for EV charging and integrate Solar ready wiring with appropriately sized conduit, roof set-asides, and labeled breakers. Use smart thermostats paired to room sensors for zoning and demand response. Install leak detection shutoffs, whole-home surge protection, and monitored energy submetering to validate performance.

Navigating Inspections, Permits, and Final Walkthroughs

You'll create a permit timeline that fits jurisdictional lead times, plan reviews, and required contingencies to eliminate stop-work orders. Next, you'll utilize an inspection readiness checklist—structural, MEP rough-ins, fire/life safety, energy code, and site controls—to verify compliance before each scheduled visit. Finally, you'll plan the punch-list and final walkthrough to check code closures, warranty documentation, and certificate of occupancy requirements.

Critical Permit Timeline Elements

While each jurisdiction establishes their own standards, a compliant permit timeline tracks a standard path: scope definition and code review, complete permit application with sealed plans, plan check and corrections, permit issuance, scheduled inspections linked to defined milestones (e.g., footing, foundation, framing, MEP rough-in, insulation, drywall, energy, and final), correction cycles as needed, and a documented final walkthrough for Certificate of Occupancy. You'll control risk by accelerating permit sequencing: align structural, energy, and MEP submittals so reviewers review a coordinated set. Identify approval contingencies in advance,flood plain requirements, septic, driveway curb cuts, or utility taps, and address them before mobilization. Retain dated logs of plan-check comments, revisions, and resubmittals. Integrate inspection holds into your schedule with float. Confirm required inspections, truss certificates, and manufacturer data are filed in advance.

Inspection Readiness Checklist

After permit sequencing is finalized, inspection readiness relies on verifiable checkpoints that align with each approved sheet. You'll organize inspections by discipline: footing, framing, rough-in MEP, insulation, drywall, and final. Begin with document prep: stamped plans on site, truss and engineered letters, energy reports, and corrected redlines. Verify erosion controls and address posting.

For rough-in stages, complete utility verification: meter sets, bonding, grounding, GFCI/AFCI placements, smoke/CO positioning, nail plate protection, fire blocking, and proper penetration sealing. Execute plumbing pressure testing, check duct tightness, and label circuits. Preserve clear access, ladder safety, and properly lit working areas.

Ahead of finals, perform appliance inspection, breaker labeling, receptacle tamper-resistance, handrails, egress, and GFCI and ARC arc-fault tests. Check grading, downspouts, and backflow devices. Close permits, capture corrections, and schedule pre-move orientation and final walkthrough.

General Questions

Do You Supply a Post-Construction Warranty and What Is Covered?

Indeed. You obtain post construction Warranty Support Coverage with established terms. We execute Punchlist Completion, maintain a Materials Guarantee, and assume Builder Liability website per code. Structural Warranty covers load‑bearing elements; Roof Warranty complies with manufacturer specs. Appliance Coverage adheres to OEM terms. You may request Warranty Transfer at closing. We deliver a Maintenance Plan with necessary inspections. Exclusions include misuse and non‑compliant alterations. Report issues without delay for documented response times and verified remediation.

How Are Subcontractors Chosen and Screened for Projects?

You pass through a rigorous pipeline: first, we assess potential firms, then review safety records and insurance, and finally verify workmanship on recent completed jobs. The uncertainty dissolves as we check licenses, trade certifications, and code compliance. We run background checks on owners and field leads, validate OSHA training, and gauge manpower and schedule reliability. We pilot them on controlled scopes, implement QA/QC hold points, and maintain only those satisfying performance and risk thresholds.

What Financing or Lender Partnerships Are Available for New Builds?

You're able to access Construction Financing via builder-approved banks and credit unions providing one-time close construction-to-permanent loans. Builder Lenders usually offer rate locks, draw schedules, and inspector-verified disbursements to manage lien risk. You'll submit plans, specs, a fixed budget, and a builder agreement; underwriting reviews appraisal "as-completed" value, contingency, and borrower reserves. Expect interest-only over construction, recourse covenants, and title updates each draw. Get details about retainage, change-order protocols, and reprice triggers.

Can You Supply References From Recent Cookeville Homeowners?

Absolutely. You can look at recent testimonials and request homeowner interviews from projects finished in the past 12-18 months. I'll furnish a pre-approved list with contact info, occupancy dates, permit numbers, and subdivision details. You can question regarding schedule adherence, change-order handling, warranty response times, and code inspection outcomes. For privacy, I'll obtain written consent before sharing. If you prefer, I'll arrange site visits to occupied homes or walkthroughs of near-completion constructions.

How Do You Deal With Change Orders Throughout Construction?

You handle a change order like a compass pivot-calculated, documented, and true. You provide a written scope revision, documenting approvals using signed forms and version-controlled logs. You estimate budget adjustments with itemized labor, materials, and contingency, then issue a revised cost breakdown. You assess timeline impacts with a critical-path update and resequencing plan. You maintain code-compliant specs, update drawings, and procure permits as needed. You refuse to proceed until approvals and deposits clear.

Wrapping Up

You arrived seeking a "reliable home builder" and, surprisingly, found trustworthiness requires code-compliance, airtight budgets, and schedules that don't time-travel. You'll vet local pros, scrutinize workmanship like a caffeinated building inspector, and insist on transparent change orders. You'll spec R-values, blower-door targets, and low-voltage runs like you planned them. Permits won't bite; you'll tame them. Final inspection? You'll come equipped with marking tape and benchmarks. Congratulations: you're not just building a house; you're commissioning a flawlessly engineered habitat.